Material: Brass with nickel plated

Sealing element: NBR

Thread Type: NPT according to ANSI/ASME B 1.20.1

Thread Type: G according to ISO 228-1/JIS B 0202

Protection class: IP54

IP68(Assemble O-ring in the tightening part )

Range of temperature: -40℃to+100℃

Application: Use slot type screwdriver tightening fixed,to seal the reserved hole

Remark: if you need other marterial of sealing element,such as silicone,EPDM,etc.pls feel free to contact us!

|

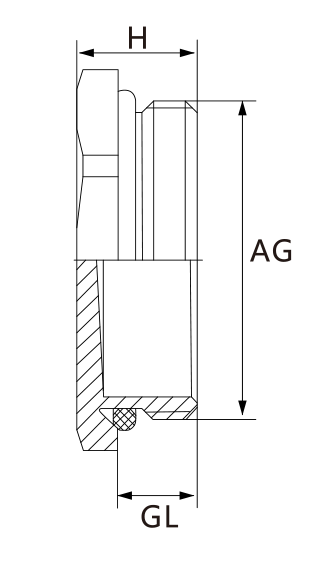

THREAD

|

Thread length (mm)

|

Height (mm)

|

Plan

diameter

(mm)

|

Thread external diameter (mm)

|

Hole size (mm)

|

|

PG7

|

5

|

8

|

14

|

12.5

|

12.5-12.8

|

|

PG9

|

6

|

9

|

17

|

15.2

|

15.2-15.5

|

|

PG11

|

6

|

9.5

|

20

|

18.6

|

18.6-18.9

|

|

PG13.5

|

6.5

|

10

|

22

|

20.4

|

20.4-20.7

|

|

PG16

|

6.5

|

10

|

24

|

22.5

|

22.5-22.8

|

|

PG21

|

7

|

10.5

|

30

|

28.3

|

28.3-28.6

|

|

PG29

|

8

|

12.5

|

41

|

37

|

37-37.3

|

|

PG36

|

8

|

13

|

50

|

47

|

47-47.3

|

|

PG42

|

9

|

15

|

58

|

54

|

54-54.3

|

|

PG48

|

10

|

16.5

|

65

|

59.3

|

59.3-59.6

|

|

M12X1.5

|

6.5

|

9.5

|

14

|

12

|

12-12.3

|

|

M14X1.5

|

6.5

|

9.5

|

16

|

14

|

14-14.3

|

|

M16X1.5

|

6.5

|

9.5

|

18

|

16

|

16-16.3

|

|

M18X1.5

|

6.5

|

9.5

|

20

|

18

|

18-18.3

|

|

M20x1.5

|

6.5

|

10

|

22

|

20

|

20-20.3

|

|

M22X1.5

|

6.5

|

10

|

24

|

22

|

22-22.3

|

|

M24X1.5

|

6.5

|

10

|

26

|

24

|

24-24.3

|

|

M25X1.5

|

7

|

10.5

|

28

|

25

|

25-25.3

|

|

M27X1.5

|

7

|

10.5

|

30

|

27

|

27-27.3

|

|

M30X1.5

|

7

|

11

|

33

|

30

|

30-30.3

|

|

M32X1.5

|

8

|

12.5

|

35

|

32

|

32-32.3

|

|

M33X1.5

|

8

|

12.5

|

36

|

33

|

33-33.3

|

|

M36X1.5

|

8

|

12.5

|

40

|

36

|

36-36.3

|

|

M40X1.5

|

8

|

13

|

44

|

40

|

40-40.3

|

|

M42X1.5

|

8

|

13

|

46

|

42

|

42-42.3

|

|

M44X1.5

|

9

|

14

|

48

|

44

|

44-44.3

|

|

M48X1.5

|

9

|

14

|

52

|

48

|

48-48.3

|

|

M50X1.5

|

9

|

15

|

54

|

50

|

50-50.3

|

|

M56X1.5

|

9

|

15

|

60

|

56

|

56-56.3

|

|

M60x1.5

|

10

|

15

|

65

|

60

|

60-60.3

|

|

M63X1.5

|

10

|

16.5

|

70

|

63

|

63-63.3

|

|

M64X1.5

|

10

|

15.5

|

67

|

64

|

64-64.3

|

|

M72X2

|

10

|

17

|

75

|

72

|

72-72.3

|

|

M80X2

|

15

|

23

|

90

|

80

|

80-80.3

|

|

M90X2

|

15

|

23

|

100

|

90

|

90-90.3

|

|

M100X2

|

15

|

24

|

110

|

100

|

100-100.3

|

|

M110X2

|

15

|

25

|

120

|

110

|

110-110.3

|

|

M120X2

|

15

|

25

|

130

|

120

|

120-120.3

|

|

M150X2

|

15

|

25

|

160

|

150

|

150-150.3

|

|

NPT1/4

|

8

|

11.5

|

17

|

13.616

|

13.7-14

|

|

NPT3/8

|

15

|

18.5

|

20

|

17.055

|

17.1-17.4

|

|

NPT1/2

|

13

|

17

|

24

|

21.224

|

21.3-21.6

|

|

NPT3/4

|

13

|

17

|

30

|

26.569

|

26.6-26.9

|

|

NPT1

|

16

|

20.5

|

41

|

33 .228

|

33.3-33.6

|

|

NPT1 1/4

|

18

|

23

|

46

|

41.985

|

42-42.3

|

|

NPT1 1/2

|

18

|

23

|

55

|

48.054

|

48.1-48.4

|

|

NPT2

|

18

|

24

|

65

|

60.092

|

60.1-60.4

|

|

NPT2 1/2

|

23

|

30

|

75

|

72.699

|

72.7-73

|

|

NPT3

|

26

|

34

|

100

|

88.608

|

88.6

|

|

NPT4

|

28

|

38

|

120

|

113.973

|

88.9

|

|

G1/4

|

7

|

10

|

17

|

13.157

|

114-114.5

|

|

G3/8

|

8

|

11.5

|

20

|

16.662

|

13.2-13.5

|

|

G1/2

|

8

|

11.5

|

24

|

20.995

|

16.7-17

|

|

G3/4

|

8

|

11.5

|

30

|

26.44 1

|

26.5-26.8

|

|

G1

|

10

|

14.5

|

41

|

33.249

|

33.3-33.6

|

|

G1 1/4

|

10

|

15

|

46

|

41.91

|

42-42 .3

|

|

G1 1/2

|

10

|

16

|

55

|

47.803

|

47.8 -48. 1

|

|

G2

|

12

|

18

|

65

|

59.614

|

59.7-60

|

|

G3

|

18

|

26

|

100

|

87 .884

|

87.9-88.5

|

|

G4

|

22

|

32

|

120

|

113.03

|

113-114

|